Preformulation & Process Design

Preformulation, formulation, and process design lay the foundation for success

Your patients are unique and so is your molecule. That’s why we apply our best science and engineering to create safe, pure, and effective drug products that are stable, convenient, cost effective, and performant.

Foundation of Success

A successful drug product needs four things:

- A formulation that is stable, convenient for the patient and healthcare provider, and delivers the correct dose at the right time and place.

- A process that is robust and cost-effective.

- Analytical methods that are specific, accurate, precise, reproducible, and robust.

- Proper documentation of development to support future transfers, changes, and understanding.

Preformulation

We start with a thorough understanding of your molecule. Preformulation starts with chemical and physical characterization of the API and then considers how the molecule will behave under different conditions. Things like solubility and stability in different pH environments, powder flow, compactability, and hygroscopicity. We want to know its vulnerabilities, strengths and weaknesses.

We don’t just measure the properties, though. We put them into a biological context to enable better formulations.

We offer a full suite of preformulation analysis, including:

- pH solubility profile

- Solubility in solvents

- Stability (heat, light, acid, base, etc.)

- logP

- pKa

- XRPD

- TGA

- DSC

- Microscopy

- Particle size analysis

- Excipient compatibility

Formulation and Process

Once we understand the strengths and weaknesses of your molecule, we consider how they interact with your therapeutic indication, patient population, healthcare provider needs, and manufacturing process conditions. We use this analysis to recommend a dosage form, formulation, and process design approach that considers all the factors holistically.

Formulation services we offer include:

- Oral Solids (Immediate or Modified Release)

- Tablets (Single or Bilayer, Hydrophilic Matrix, MUPS)

- Capsules (Powder, Granules, Pellets, Minitablets)

- Sachets (Powder, Granules or Pellets)

- Oral Liquids (Solutions or Suspensions)

- Inhalable Powders (Spray Dried Dispersions)

From Concept to Control

Our scientists work to ensure manufacturability from the earliest stages. We balance theoretical models with practical execution, designing processes that work in development and transfer seamlessly to GMP manufacturing and scale up.

We systematically develop manufacturing processes that ensure product quality through:

- Process Architecture

- Mapping your target product profile to an optimal sequence of unit operations with clear process flow and control strategy

- Parameter Definition

- Identifying critical process parameters and establishing operating ranges that ensure consistent product quality

- Risk-Based Development

- Applying scientific and engineering principles to understand process sensitivities and build appropriate controls

- Scale-Up Strategy

- Designing processes with commercial manufacturing in mind, minimizing transfer risks

- Process Demonstration

- Executing engineering batches to confirm reproducibility and establish process capability

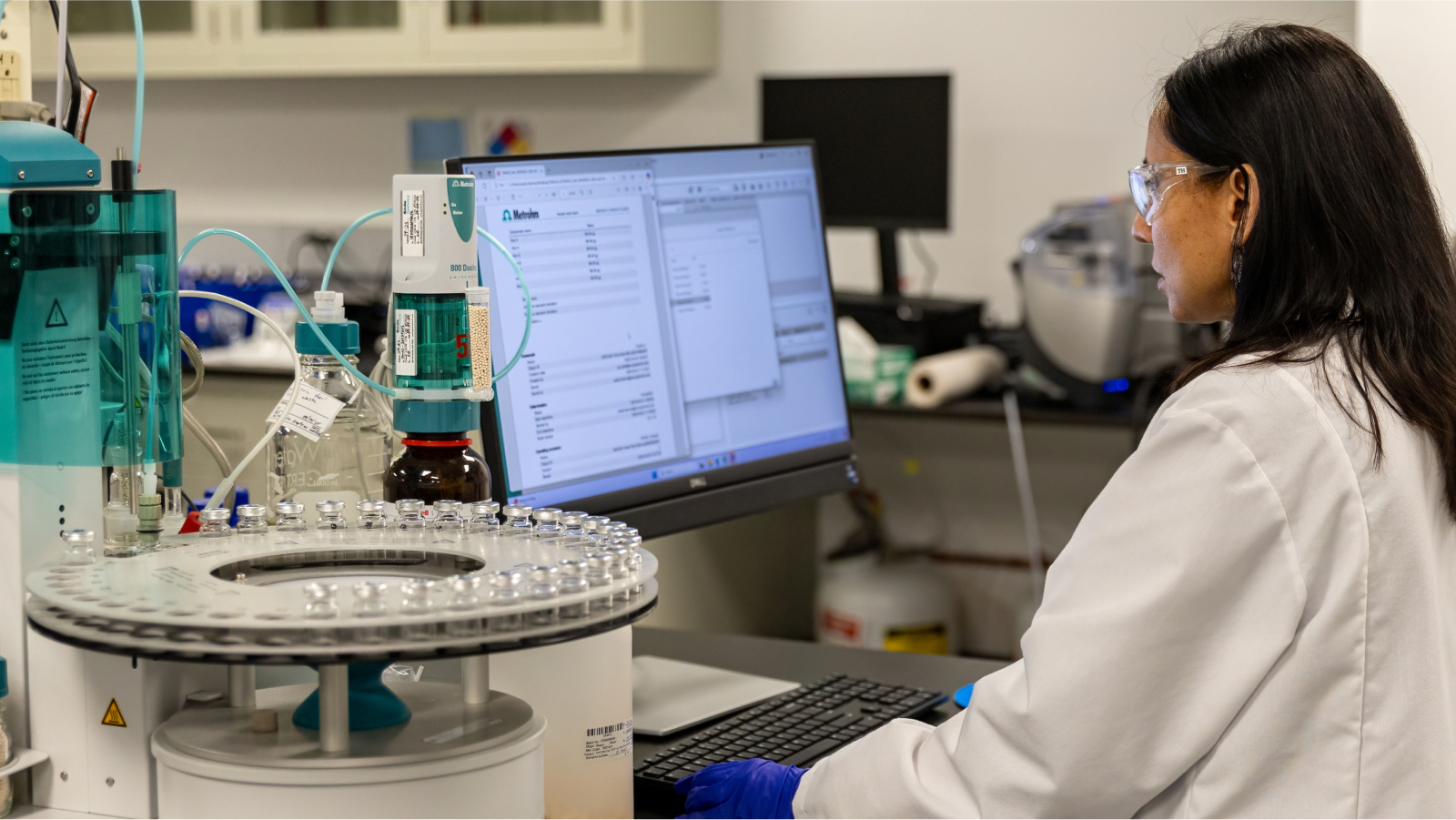

Analytical Support is On-site

All our formulation and process work is supported by comprehensive, onsite analytical development, validation and testing to minimize the lag between running a batch and getting your results.

Design • Develop • Manufacture

Let's build something remarkable